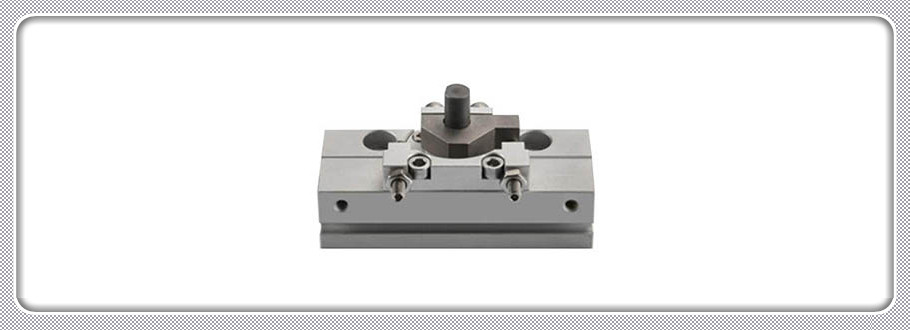

1. Type Selection The correct type of cylinder should be selected according to the working requirements and conditions.The buffer cylinder should be selected if there is no impact phenomenon and impact noise when the cylinder reaches the stroke terminal.Light weight is required, light cylinder should be selected; The installation space is narrow and the stroke is short. Thin cylinder is optional.Transverse load, optional cylinder with guide rod;High braking accuracy is required, locking cylinder should be selected;Piston rod rotation is not allowed, optional cylinder with the function of no rotation of the rod;Heat resistant cylinder should be used in high temperature environment.In a corrosive environment, corrosion - resistant cylinder should be selected.In bad conditions such as dust, it is necessary to install a dust cover on the extension end of piston rod.No oil or no oil lubrication cylinder should be used when no pollution is required. 2. Installation form According to the installation location, use purpose and other factors decided.In general, a fixed cylinder is used.When it is necessary to rotate continuously with the working mechanism (such as lathe, grinder, etc.), the rotary cylinder should be selected.When the piston rod is required to move in a straight line, but also need to make circular swing, shaft pin cylinder is selected.When there are special requirements, the corresponding special cylinder should be selected. 3. The force is the choice of cylinder diameter.According to the size of the load force to determine the cylinder output thrust and tension.In general, according to the external load theory to balance the required cylinder force, according to different speeds to choose different load rate, so that the cylinder output force a little margin.The cylinder diameter is too small, the output force is not enough, but the cylinder diameter is too large, which makes the equipment bulky, increases the cost, increases the gas consumption, and wastes energy.In the fixture design, the force expansion mechanism should be used as far as possible to reduce the cylinder size. • Cylinder diameter: 6. 8 • External limiter can be attached • A variety of swing angles are available • Flexible piping position, which can be concentrated on the front or side

1. Type Selection The correct type of cylinder should be selected according to the working requirements and conditions.The buffer cylinder should be selected if there is no impact phenomenon and impact noise when the cylinder reaches the stroke terminal.Light weight is required, light cylinder should be selected; The installation space is narrow and the stroke is short. Thin cylinder is optional.Transverse load, optional cylinder with guide rod;High braking accuracy is required, locking cylinder should be selected;Piston rod rotation is not allowed, optional cylinder with the function of no rotation of the rod;Heat resistant cylinder should be used in high temperature environment.In a corrosive environment, corrosion - resistant cylinder should be selected.In bad conditions such as dust, it is necessary to install a dust cover on the extension end of piston rod.No oil or no oil lubrication cylinder should be used when no pollution is required. 2. Installation form According to the installation location, use purpose and other factors decided.In general, a fixed cylinder is used.When it is necessary to rotate continuously with the working mechanism (such as lathe, grinder, etc.), the rotary cylinder should be selected.When the piston rod is required to move in a straight line, but also need to make circular swing, shaft pin cylinder is selected.When there are special requirements, the corresponding special cylinder should be selected. 3. The force is the choice of cylinder diameter.According to the size of the load force to determine the cylinder output thrust and tension.In general, according to the external load theory to balance the required cylinder force, according to different speeds to choose different load rate, so that the cylinder output force a little margin.The cylinder diameter is too small, the output force is not enough, but the cylinder diameter is too large, which makes the equipment bulky, increases the cost, increases the gas consumption, and wastes energy.In the fixture design, the force expansion mechanism should be used as far as possible to reduce the cylinder size. • Cylinder diameter: 6. 8 • External limiter can be attached • A variety of swing angles are available • Flexible piping position, which can be concentrated on the front or side