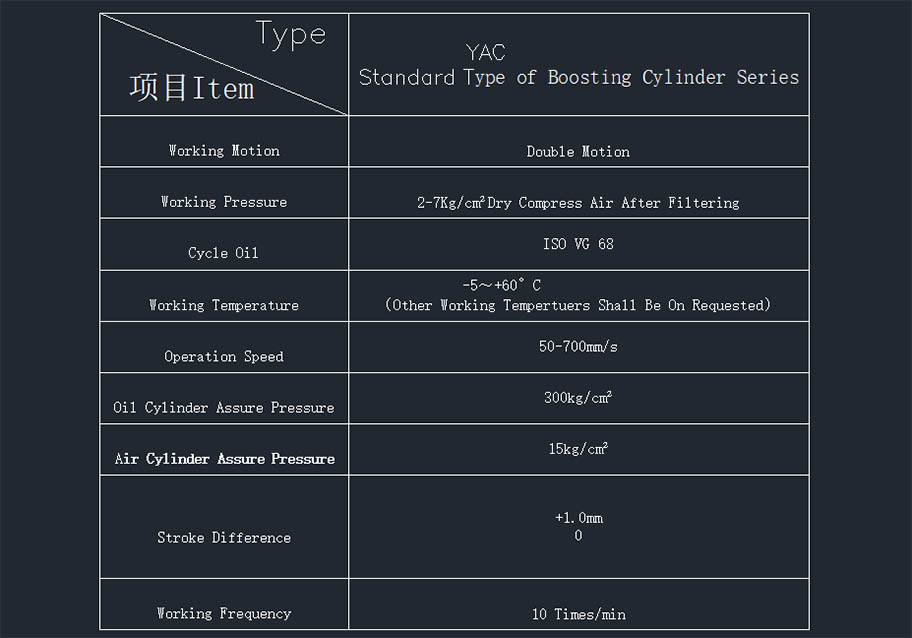

The pressurized cylinder USES the general air pressure to achieve the higher force of the hydraulic cylinder without the need for hydraulic unit. Supercharged cylinders can be divided into: pre-pressure supercharged cylinders, direct pressure supercharged cylinders, travel adjustable supercharged cylinders, increased backhaul pull supercharged cylinders, compact parallel supercharged cylinders, mini supercharged cylinders, quick supercharged cylinders, and oil-gas isolated supercharged cylinders. The working frequency of the pressurized cylinder is generally 10~70 times/min according to different stroke and cylinder diameter. Operation speed: 50~1000mm/s

The pressurized cylinder USES the general air pressure to achieve the higher force of the hydraulic cylinder without the need for hydraulic unit. Supercharged cylinders can be divided into: pre-pressure supercharged cylinders, direct pressure supercharged cylinders, travel adjustable supercharged cylinders, increased backhaul pull supercharged cylinders, compact parallel supercharged cylinders, mini supercharged cylinders, quick supercharged cylinders, and oil-gas isolated supercharged cylinders. The working frequency of the pressurized cylinder is generally 10~70 times/min according to different stroke and cylinder diameter. Operation speed: 50~1000mm/s

Speed is fast The operating speed is faster than hydraulic transmission and more stable than pneumatic transmission; Easy to use Cylinder block installation is simple, easy to adjust output, easy to use and maintain; Make big In the same way, it can reach the high pressure of the hydraulic press, and the non-pure pressure system can reach it. The price is low The unit price of the equipment is lower than that of the hydraulic system. Easy to maintain Because the structure is simple, it is easier to maintain than the hydraulic system. Low energy consumption When continuous pressure or stop operation, it is not necessary for the motor to run continuously like the pure hydraulic system, so energy can be saved and the power source is convenient and easy to be obtained. The actual energy consumption is equivalent to 10%-30% of the hydraulic system; There is no leakage Easy energy conversion, can achieve zero leakage without worrying about environmental pollution; Don't loss modulus In order to meet the needs of the process, the punching pressure and working stroke can reach stepless adjustable within the specified range; Easy installation There are a variety of ways to install, according to the different workplace can be installed at any Angle and position; A soft landing Stamping soft placement technology, so that the movement noise and protect your mold; Few breakdowns No trouble of oil pressure system temperature rise; The space is little Compared with ordinary cylinder and hydraulic station, the occupied space area can be less than 50%;

Speed is fast The operating speed is faster than hydraulic transmission and more stable than pneumatic transmission; Easy to use Cylinder block installation is simple, easy to adjust output, easy to use and maintain; Make big In the same way, it can reach the high pressure of the hydraulic press, and the non-pure pressure system can reach it. The price is low The unit price of the equipment is lower than that of the hydraulic system. Easy to maintain Because the structure is simple, it is easier to maintain than the hydraulic system. Low energy consumption When continuous pressure or stop operation, it is not necessary for the motor to run continuously like the pure hydraulic system, so energy can be saved and the power source is convenient and easy to be obtained. The actual energy consumption is equivalent to 10%-30% of the hydraulic system; There is no leakage Easy energy conversion, can achieve zero leakage without worrying about environmental pollution; Don't loss modulus In order to meet the needs of the process, the punching pressure and working stroke can reach stepless adjustable within the specified range; Easy installation There are a variety of ways to install, according to the different workplace can be installed at any Angle and position; A soft landing Stamping soft placement technology, so that the movement noise and protect your mold; Few breakdowns No trouble of oil pressure system temperature rise; The space is little Compared with ordinary cylinder and hydraulic station, the occupied space area can be less than 50%;