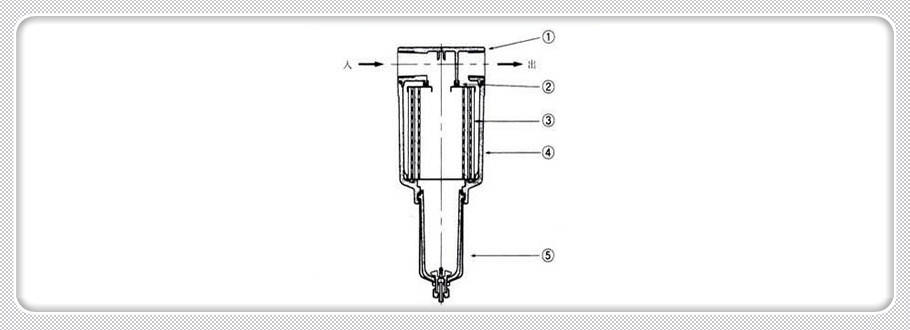

SMC microfog separator of good effect, suitable for large refrigeration system, its structure is shown in Figure 7-3.The exhaust of the compressor goes into the cylinder along the tangent direction through the inlet pipe of the oil separator and then rotates at a high speed along the spiral guide vane and flows from top to bottom.Under the action of centrifugal force, the oil droplets with higher density in the exhaust gas are separated from the cylinder wall and deposited along the wall at the bottom of the cylinder.The vapor is extracted by a porous plate in the gas outlet pipe at the center of the cylinder.The cylinder side is equipped with a ball float valve. When the oil level rises to the upper limit, the lubricating oil opens the spool through the ball float valve and automatically discharges oil to the crankcase or oil collector of the compressor.Some of the oil separator is also provided with a cooling jacket, in which the mixed steam is cooled by the cooling water and further separated by reducing the flow rate and changing the flow direction. The application of microfog separator also increases gradually.The control method of three - phase separator is different with different structure. The control principles of the two typical separators are as follows: (1) After the mixture of oil, gas and water enters the separator, the inlet shunt divides the mixture into roughly vapor-liquid two phases, and the liquid phase enters the liquid collecting part.The catchment portion has enough volume to allow free water to settle to the bottom to form a water layer above which is the crude oil and an emulsion layer containing smaller droplets. Crude oil and emulsion spilled over the baffle.The oil level downstream of the baffle is controlled at a constant height by the oil level controller.The water is discharged from the outlet upstream of the baffle, and the oil-water interface controller controls the opening of the drainage valve to keep the oil-water interface at the specified height.The pressure of the separator is controlled by a valve in the natural gas line. The spread of the oil particles by the filter material, directly blocked by filter material and the condensation of inertia collision mechanism, make the compressed air in the suspended particles quickly condenses into lard oil drops and oil under the action of gravity concentration in oil at the bottom of the core, by importing returns at the bottom of the sunken place return pipe head lubricating oil system, so that more pure and oil-free compressed air compressor discharge.The solid particles in the compressed air are trapped in the filter layer when passing through the oil core, which leads to the increasing pressure difference (resistance) of the oil core.With the increase of the service time of the oil separator, when the pressure difference of the oil separator reaches 0.08 to 0.1mpa, the filter element must be replaced, otherwise the operating cost (power consumption) of the compressor will increase.

SMC microfog separator of good effect, suitable for large refrigeration system, its structure is shown in Figure 7-3.The exhaust of the compressor goes into the cylinder along the tangent direction through the inlet pipe of the oil separator and then rotates at a high speed along the spiral guide vane and flows from top to bottom.Under the action of centrifugal force, the oil droplets with higher density in the exhaust gas are separated from the cylinder wall and deposited along the wall at the bottom of the cylinder.The vapor is extracted by a porous plate in the gas outlet pipe at the center of the cylinder.The cylinder side is equipped with a ball float valve. When the oil level rises to the upper limit, the lubricating oil opens the spool through the ball float valve and automatically discharges oil to the crankcase or oil collector of the compressor.Some of the oil separator is also provided with a cooling jacket, in which the mixed steam is cooled by the cooling water and further separated by reducing the flow rate and changing the flow direction. The application of microfog separator also increases gradually.The control method of three - phase separator is different with different structure. The control principles of the two typical separators are as follows: (1) After the mixture of oil, gas and water enters the separator, the inlet shunt divides the mixture into roughly vapor-liquid two phases, and the liquid phase enters the liquid collecting part.The catchment portion has enough volume to allow free water to settle to the bottom to form a water layer above which is the crude oil and an emulsion layer containing smaller droplets. Crude oil and emulsion spilled over the baffle.The oil level downstream of the baffle is controlled at a constant height by the oil level controller.The water is discharged from the outlet upstream of the baffle, and the oil-water interface controller controls the opening of the drainage valve to keep the oil-water interface at the specified height.The pressure of the separator is controlled by a valve in the natural gas line. The spread of the oil particles by the filter material, directly blocked by filter material and the condensation of inertia collision mechanism, make the compressed air in the suspended particles quickly condenses into lard oil drops and oil under the action of gravity concentration in oil at the bottom of the core, by importing returns at the bottom of the sunken place return pipe head lubricating oil system, so that more pure and oil-free compressed air compressor discharge.The solid particles in the compressed air are trapped in the filter layer when passing through the oil core, which leads to the increasing pressure difference (resistance) of the oil core.With the increase of the service time of the oil separator, when the pressure difference of the oil separator reaches 0.08 to 0.1mpa, the filter element must be replaced, otherwise the operating cost (power consumption) of the compressor will increase.  Oil mist separator is a kind of environmental protection product used for machining and purifying oil mist. The product is made of efficient essence filter material and high quality click combination In other words, the oil mist separator is to extract the oil and gas through the wind wheel, and then achieve purification and separation. The physical filtration method is adopted to return the filtered oil mist to the oil cylinder The oil mist and water mist produced by the machine can be recovered at the same time. The machine has the characteristics of high efficiency and energy saving lamp. It can achieve good results at the same time of the rapid development of machining. The filter material of oil mist separator consists of more than three kinds of filter material, there are primary, intermediate, senior lamp oil mist filter material process.Represents the different size of the filter material, the higher the better. Characteristics of oil mist separator 1. Efficient and durable filtering effect, imported filtering material: compared with e-books and its purification efficiency will not change much 2. The performance of the equipment is long-lasting and stable. Click the motor with high protection and motor protector to make the machine stable and durable 3. Easy to maintain, the maintenance of the machine is very simple, it only takes less than 30 seconds to replace and clean the filter material. 4. Maintenance cost: one year's maintenance cost is low and the machine has good effect, compared with the classical and electronic ones, and the initial investment is large. 5. Simple and reliable installation. It only takes one hour to install, and say goodbye to the troublesome disassembly and installation procedures 6. Easy and fast maintenance, no static high voltage and fragile parts in the machine. High protection of the wind wheel makes the machine very safe 7. Machine purification of the state of oil mist and dust wide applicability, is the first choice of many factories

Oil mist separator is a kind of environmental protection product used for machining and purifying oil mist. The product is made of efficient essence filter material and high quality click combination In other words, the oil mist separator is to extract the oil and gas through the wind wheel, and then achieve purification and separation. The physical filtration method is adopted to return the filtered oil mist to the oil cylinder The oil mist and water mist produced by the machine can be recovered at the same time. The machine has the characteristics of high efficiency and energy saving lamp. It can achieve good results at the same time of the rapid development of machining. The filter material of oil mist separator consists of more than three kinds of filter material, there are primary, intermediate, senior lamp oil mist filter material process.Represents the different size of the filter material, the higher the better. Characteristics of oil mist separator 1. Efficient and durable filtering effect, imported filtering material: compared with e-books and its purification efficiency will not change much 2. The performance of the equipment is long-lasting and stable. Click the motor with high protection and motor protector to make the machine stable and durable 3. Easy to maintain, the maintenance of the machine is very simple, it only takes less than 30 seconds to replace and clean the filter material. 4. Maintenance cost: one year's maintenance cost is low and the machine has good effect, compared with the classical and electronic ones, and the initial investment is large. 5. Simple and reliable installation. It only takes one hour to install, and say goodbye to the troublesome disassembly and installation procedures 6. Easy and fast maintenance, no static high voltage and fragile parts in the machine. High protection of the wind wheel makes the machine very safe 7. Machine purification of the state of oil mist and dust wide applicability, is the first choice of many factories| Model | YAMF250〜850 |

| Fluid | Compressed Air |

| Max. Press. | l.0Mpa(10.2kgt/cm2) |

| Min. Press. | 0.05Mpa(0.5kgf/cm2) |

| Proof Press. | l.5Mpad5.3kgf/cm5) |

| Amb. &Media Temp. | 0~6℃ |

| Filteration | 0.01µm Remove 95% |

| Scavening Particle Size | 99% |

| Element Life | 2years or At Press.Differential 0.1Mpa(1kgf/cm2) |

| Auto Drain Type:0.15Mpa(1.5kgf/cm2) | |

| Model | Size | Part | Repair Parts(Option) | ||||

| Manual Drain Type | Auto Drain Type | Flow Rate(Umin) | Pipe Size(RC(PT) | Wt.(Kg) | Bracket | Auto Drain Float | Element |

| YAMF250-02 | YAMF250-02D | 500 | 1/4" | 0.55 | BM-25 | YAD40 | YAMF-EL250 |

| YAMF250-03 | YAMF250-03D | 500 | 3/8" | 0.55 | BM-25 | YAD40 | YAMF-EL250 |

| YAMF350-03 | YAMF350-03D | 1000 | 3/8" | 0.90 | BM-35 | YAD40 | YAMF-EL350 |

| YAMF350-04 | YAMF350-04D | 1000 | 1/2" | 0.90 | BM-35 | YAD40 | YAMF-EL350 |

| YAMF450-04 | YAMF450-04D | 2000 | 1/2" | 1.40 | BM-45 | YAD40 | YAMF-EL450 |

| YAMF450-06 | YAMF450-06D | 2000 | 3/4" | 1.40 | BM-45 | YAD40 | YAMF-EL450 |

| YAMF550-06 | YAMF550-06D | 3500 | 3/4" | 2.10 | BM-55 | YAD40 | YAMF-EL550 |

| YAMF550-10 | YAMF550-10D | 3500 | 1" | 2.10 | BM-55 | YAD40 | YAMF-EL550 |

| YAMF650-14 | YAMF650-14D | 6000 | 1½" | 5.00 | BM-65 | YAD40 | YAMF-EL650 |

| YAMF850-14 | YAMF850-14D | 12000 | 1½" | 11.50 | BM-85 | YAD40 | YAMF-EL850 |

| YAMF850-20 | YAMF850-20D | 12000 | 2" | 11.50 | BM-85 | YAD40 | YAMF-EL850 |