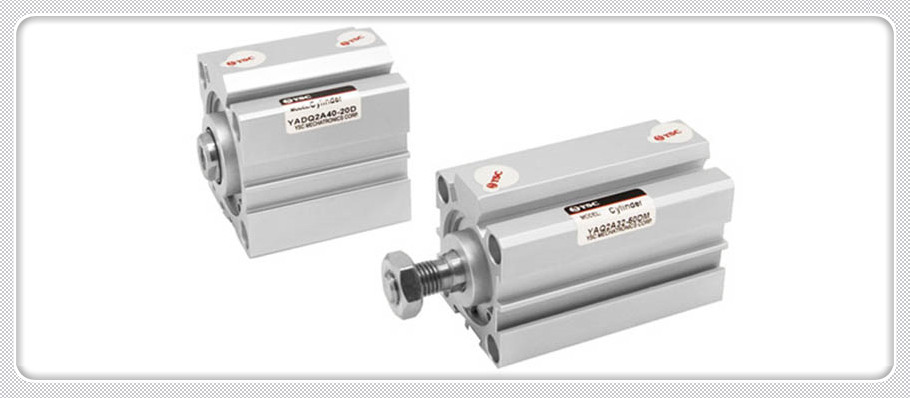

1) cylinder The inner diameter of the cylinder represents the output force of the cylinder.The piston should make a smooth reciprocating slide in the cylinder, and the surface roughness of the cylinder inner surface should reach RA0.8um.For steel tube cylinder, the inner surface should be plated with hard chrome to reduce friction and wear, and prevent corrosion. Cylinder material in addition to the use of high carbon steel pipe, or high strength aluminum alloy and brass.Small cylinders have stainless steel tubes.Cylinders with magnetic switches or cylinders used in corrosion resistant environments shall be made of stainless steel, aluminum alloy or brass. 2) end cover The end cover is provided with an inlet and outlet, and some are also equipped with a buffer mechanism inside the end cover.Sealing ring and dustproof ring are provided on the side cover of the rod to prevent air leakage from the piston rod and prevent external dust from mixing into the cylinder.The rod side cover is provided with a guide sleeve to improve the guide accuracy of the cylinder, bear a small amount of transverse load on the piston rod, reduce the piston rod bending, prolong the service life of the cylinder.Guide sleeves are usually made from sintered oil-bearing alloy, tipped copper castings.The end cover used to be malleable iron, in order to reduce the weight and rust, often used aluminum alloy die casting, miniature cylinder has the use of brass material. 3) the piston The piston is a pressurized part in a thin cylinder.To prevent the left and right cavities of the piston from channeling each other, a piston sealing ring is provided.The wear ring on the piston can improve the guide of the cylinder, reduce the wear of the piston seal ring, and reduce the friction resistance.Wear-resisting ring is made of polyurethane, polytetrafluoroethylene, cloth synthetic resin and other materials.The width of the piston is determined by the size of the seal ring and the length of the necessary sliding section.The sliding part is too short, easy to cause early wear and jam.The material of piston is usually aluminum alloy and cast iron. The piston of small cylinder is made of brass. 4) Piston rod Piston rod is the most important stressed part in thin cylinder.High carbon steel with hard chrome plating or stainless steel is usually used to prevent corrosion and improve the wear resistance of the sealing ring. 5) Sealing ring Rotary or reciprocating movement of the parts of the seal is called dynamic seal, static parts of the seal known as static seal. Applications of thin cylinder: printing (tension control), semiconductor (spot welding machine, chip grinding), automatic control, robot, etc.

1) cylinder The inner diameter of the cylinder represents the output force of the cylinder.The piston should make a smooth reciprocating slide in the cylinder, and the surface roughness of the cylinder inner surface should reach RA0.8um.For steel tube cylinder, the inner surface should be plated with hard chrome to reduce friction and wear, and prevent corrosion. Cylinder material in addition to the use of high carbon steel pipe, or high strength aluminum alloy and brass.Small cylinders have stainless steel tubes.Cylinders with magnetic switches or cylinders used in corrosion resistant environments shall be made of stainless steel, aluminum alloy or brass. 2) end cover The end cover is provided with an inlet and outlet, and some are also equipped with a buffer mechanism inside the end cover.Sealing ring and dustproof ring are provided on the side cover of the rod to prevent air leakage from the piston rod and prevent external dust from mixing into the cylinder.The rod side cover is provided with a guide sleeve to improve the guide accuracy of the cylinder, bear a small amount of transverse load on the piston rod, reduce the piston rod bending, prolong the service life of the cylinder.Guide sleeves are usually made from sintered oil-bearing alloy, tipped copper castings.The end cover used to be malleable iron, in order to reduce the weight and rust, often used aluminum alloy die casting, miniature cylinder has the use of brass material. 3) the piston The piston is a pressurized part in a thin cylinder.To prevent the left and right cavities of the piston from channeling each other, a piston sealing ring is provided.The wear ring on the piston can improve the guide of the cylinder, reduce the wear of the piston seal ring, and reduce the friction resistance.Wear-resisting ring is made of polyurethane, polytetrafluoroethylene, cloth synthetic resin and other materials.The width of the piston is determined by the size of the seal ring and the length of the necessary sliding section.The sliding part is too short, easy to cause early wear and jam.The material of piston is usually aluminum alloy and cast iron. The piston of small cylinder is made of brass. 4) Piston rod Piston rod is the most important stressed part in thin cylinder.High carbon steel with hard chrome plating or stainless steel is usually used to prevent corrosion and improve the wear resistance of the sealing ring. 5) Sealing ring Rotary or reciprocating movement of the parts of the seal is called dynamic seal, static parts of the seal known as static seal. Applications of thin cylinder: printing (tension control), semiconductor (spot welding machine, chip grinding), automatic control, robot, etc.